Capability

RD Design

ANSYS HFSS Finite Element Method software

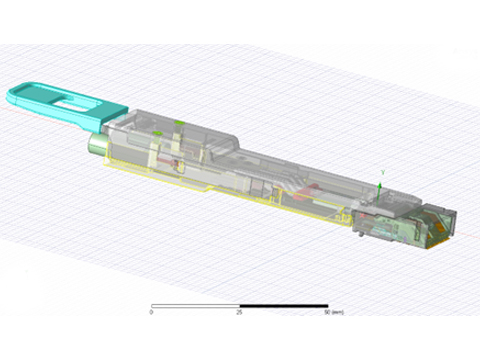

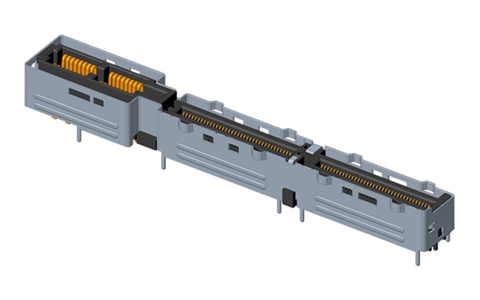

3D model design

Version:ANSYS 2023R2

Software function:Signal & Power integrity design、High-speed Cable & connector design、High Accuracy 3D Electromagnetic analysis software

Cable:

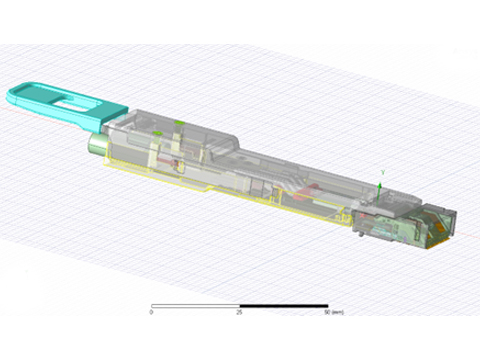

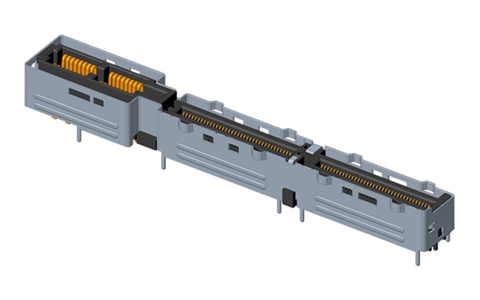

Cable +connector 3D model

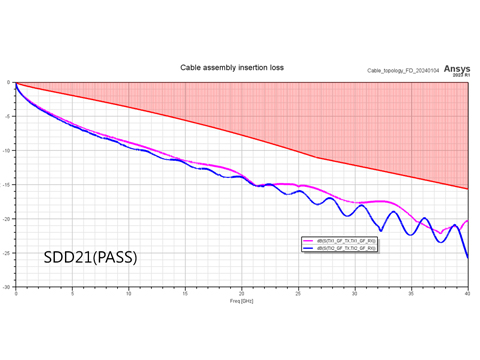

Cable Electrical characteristics plot:Differential to common-mode return loss(SCD11)

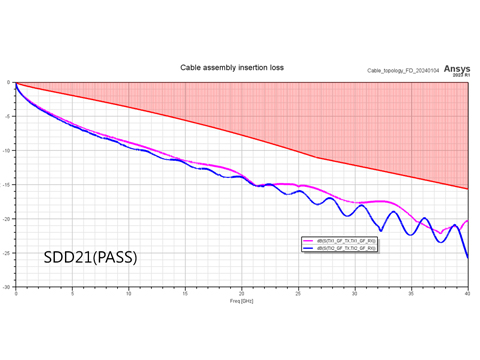

Cable Insertion loss

Connecter:

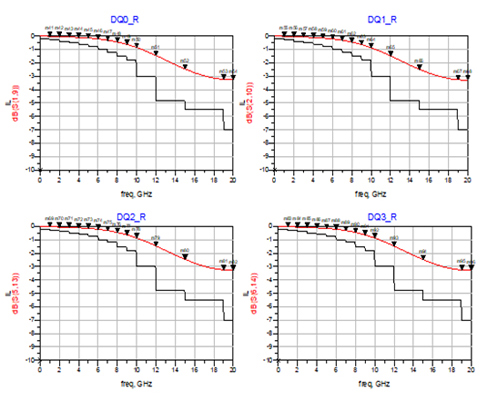

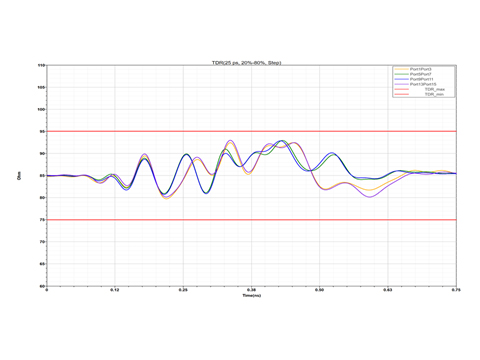

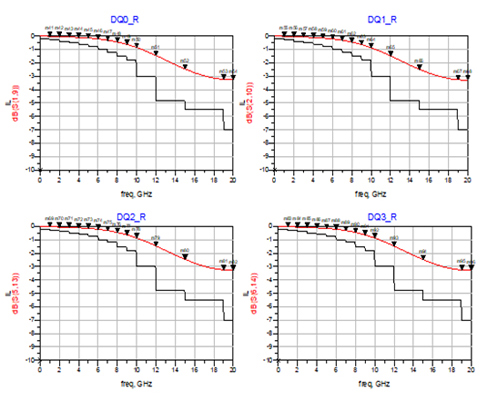

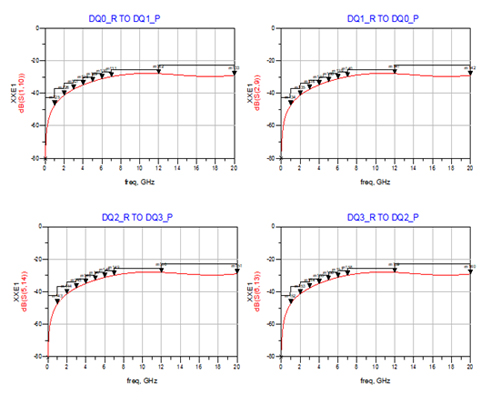

Insertion Loss : Simulation

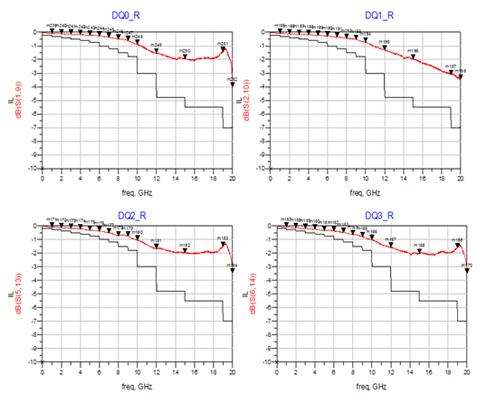

Insertion Loss : Measurement

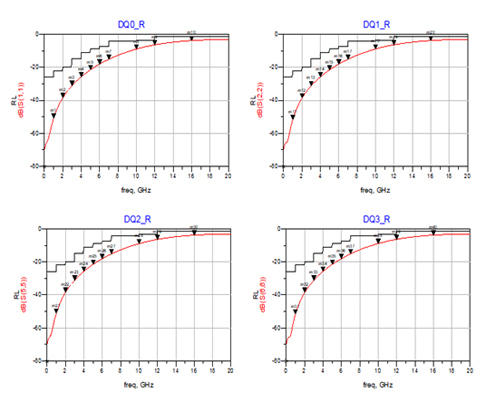

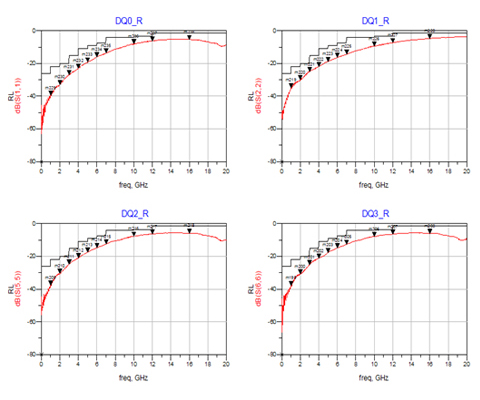

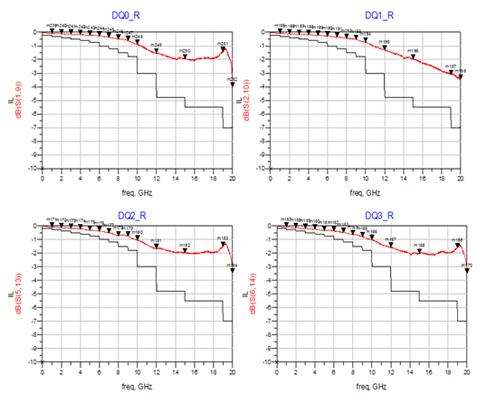

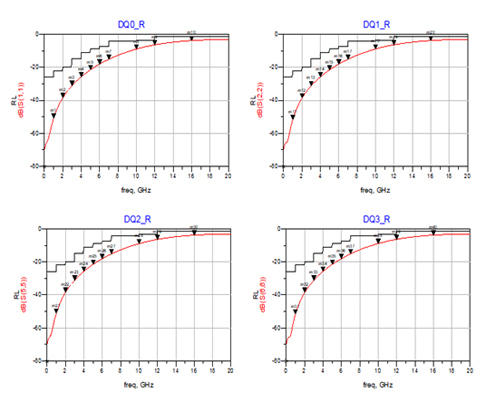

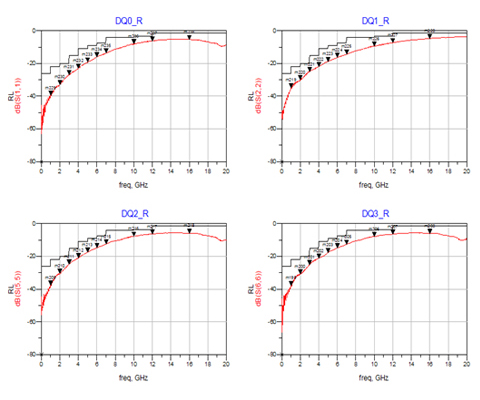

Return Loss : Simulation

Return Loss : Measurement

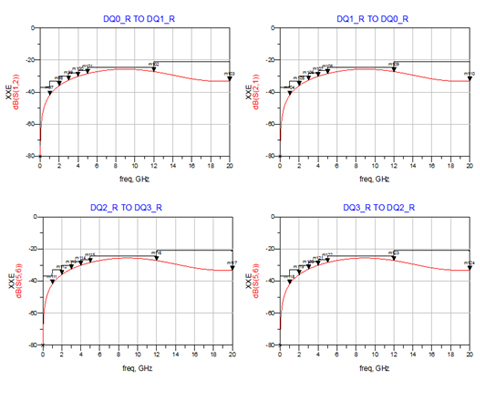

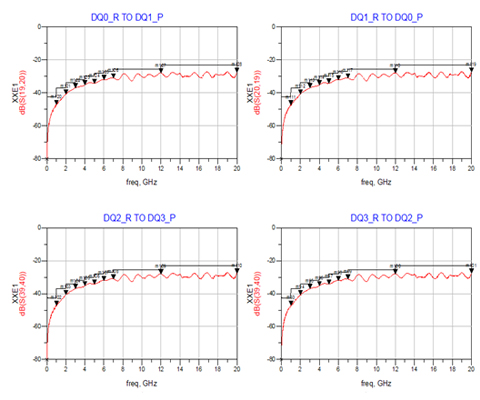

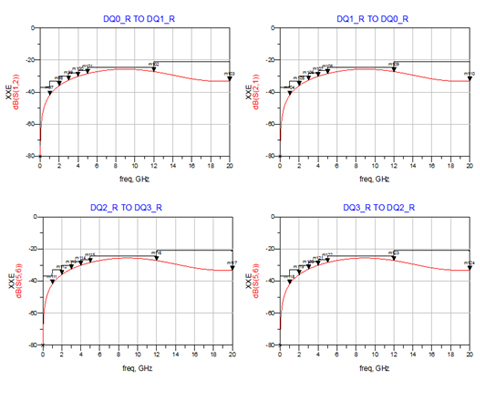

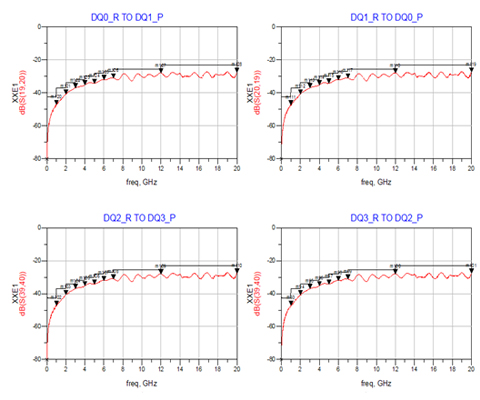

NEXT : Simulation

NEXT : Measurement

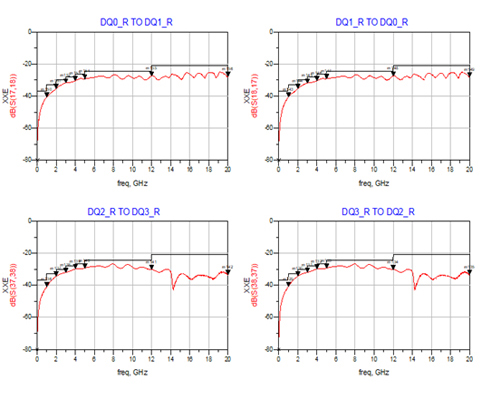

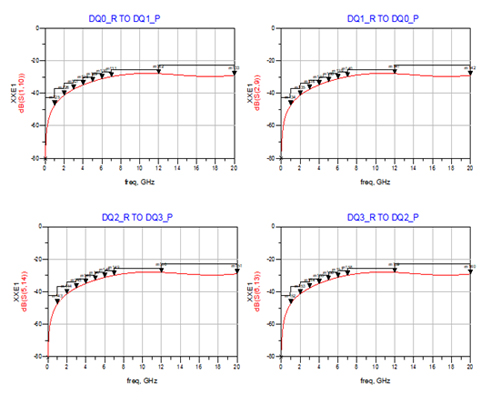

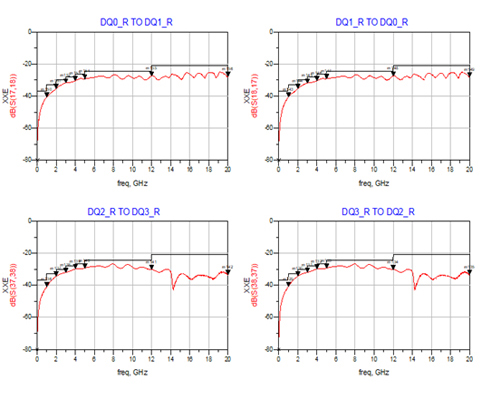

FEXT : Simulation

FEXT : Measurement

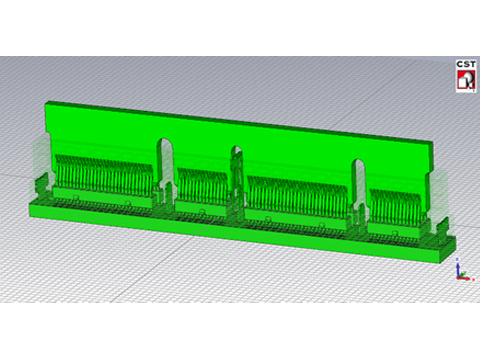

CST Studio Suite analysis software

Mold flow analysis

Version:CST 2018(Update to CST2024)

Software function:Signal & Power integrity design、High-speed Cable & connector design、High Accuracy 3D Electromagnetic analysis software

3D CAD Software

Version:Creo Parametric 10

Software function:3D solid design, sheet metal design, 2D drawing, parts assembly, interference analysis, product rendering

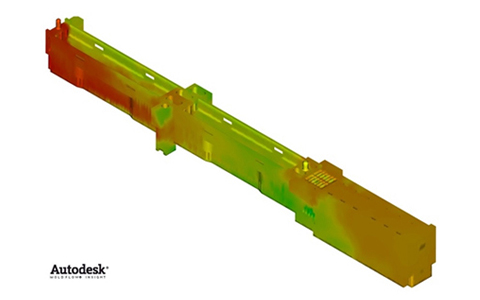

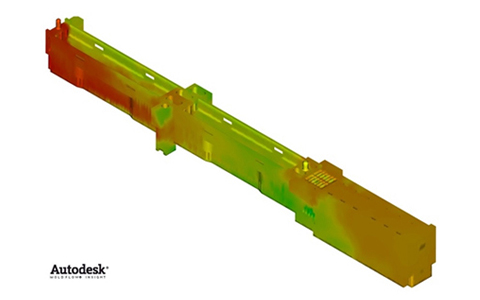

Autodesk Moldflow Insight

Version:Autodesk Moldflow Insight 2010

Software function:Plastic flow, warpage, cooling, weld lines, air envelope and flow channel optimization analysis

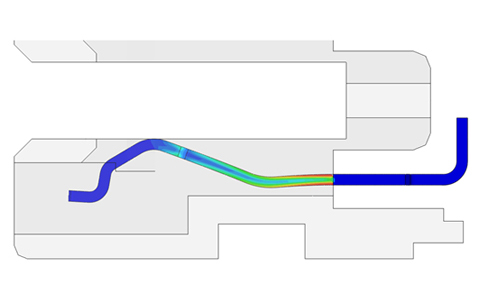

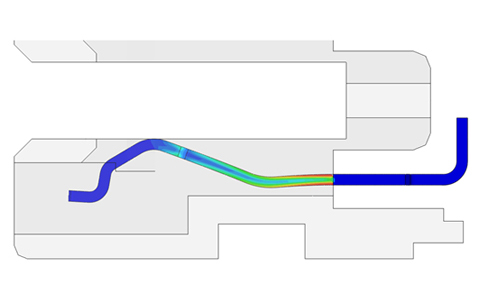

SIMULIA Abaqus CAE

Terminal Stress Analysis

Version:SIMULIA Abaqus 6.9

Software function:Analysis of static, dynamic, heat transfer, contact, etc. structures

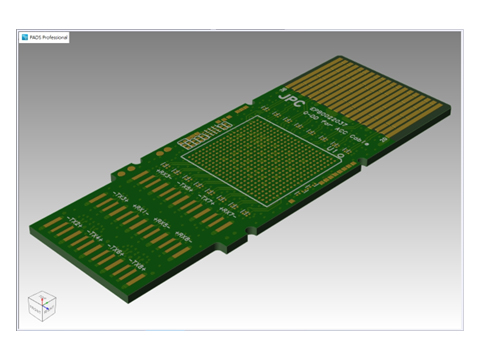

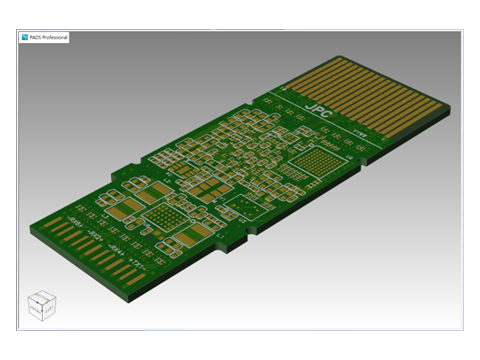

PCB Layout

Version: OrCAD, Allegro, PADS

Software function : Schematic Design, PCB Layout, 3D &, 2D drawing, Parts assembly.

Associations and Certifications

Instruments and equipment

High-voltage wire harness processing for wire outer skin stripping

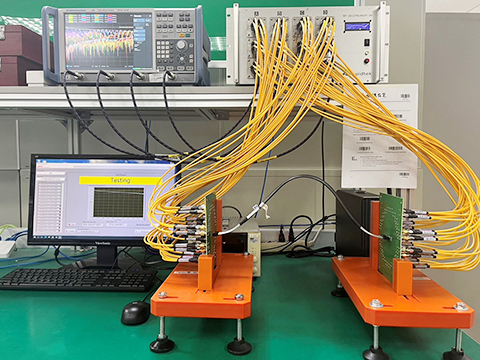

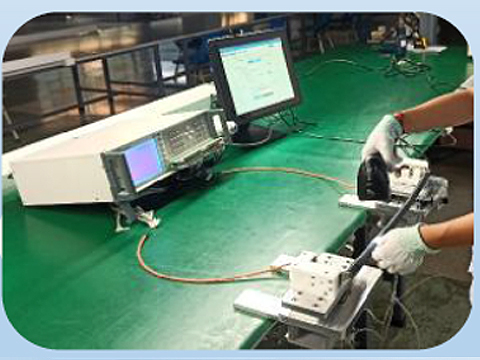

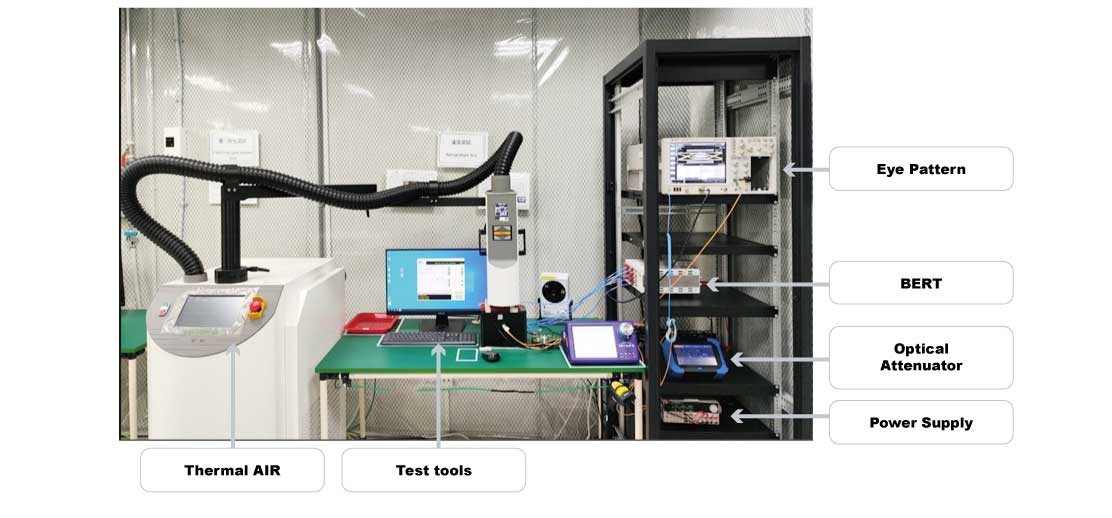

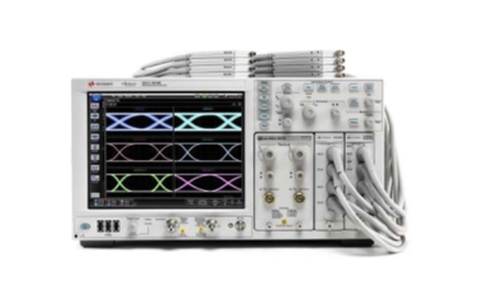

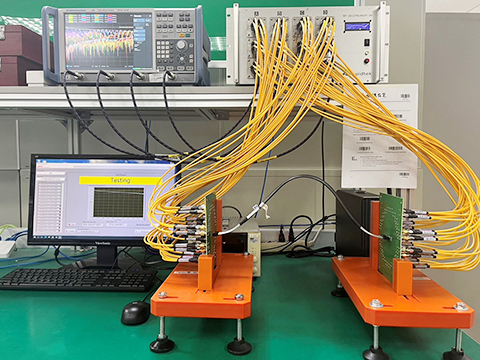

SI Measure

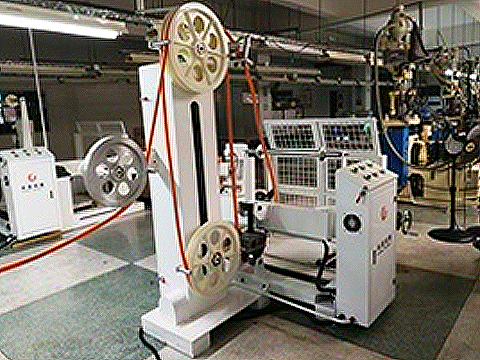

Injection Machine

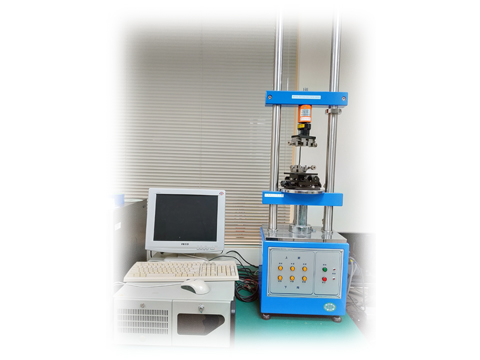

Press Machine

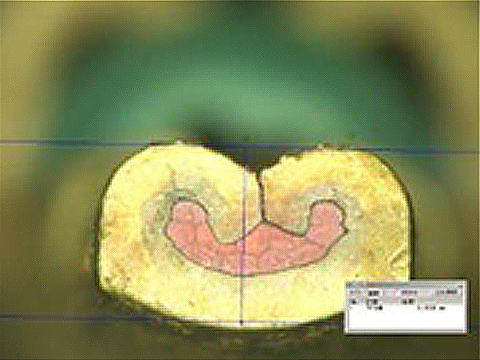

Highly Precision Mold Workshop Equipment

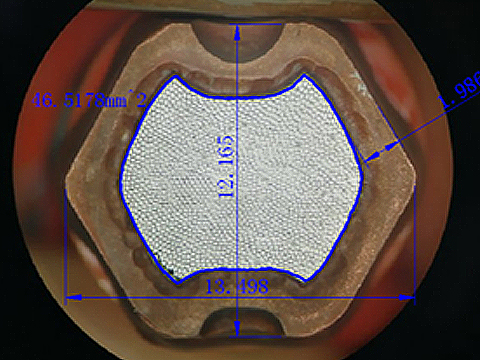

- .Tools and super-hard materials are ground and finished. The grinding wheel is made of diamond or white jade; the optical projection magnification mode is used for imaging, which can be magnified up to 40 times for imaging.

- .The related processing accuracy can be controlled within ±0.0001mm.

High-precision optical grinder

Manufacturer: WASINNO

High-precision EDM

Manufacturer: MITSUBSHI

5-axis CNC

Manufacturing place: Taiwan

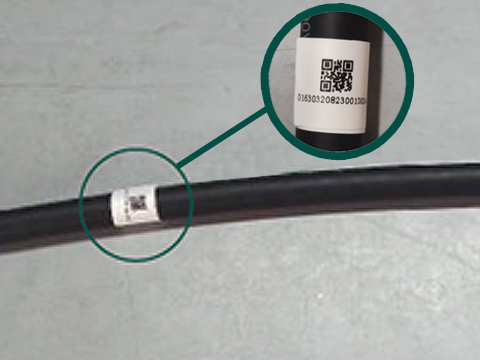

Extremely fine (AWG42~46#) wire harness production and processing equipment

- .The main working principle of the laser machine is to use different laser principles inside the equipment to process the outer back of the wire without damaging the internal wire core. Can be fixed in length and depth. The wires are too thin to use conventional equipment.

- .The main working principle of the welding machine is that the equipment welds the wires to the connector through the principle of timed high temperature protection. The main welding mode is Hot-bar welding.

- .The main products are used in medical equipment.

Wire processing equipment: CO2 laser machine

Wire welding equipment: welding machine